Blog

Ford Diagnostic scan tool

Evolution of Ford Cars Diagnostic scan Tool: From Simple Beginnings to Artificial Intelligence

Discover the history of Ford diagnostic scan tools, from the early OBD1 systems to advanced VCM devices. Learn about the latest technologies and the impact of AI on automotive diagnostics.

Imagine a world without automotive diagnostic tools! A world where diagnosing a simple car problem could take days. Today, diagnosing car troubles is easy and straightforward thanks to tremendous technological advancements. In this article, we’ll take you on a journey through time to explore the history of Ford diagnostic tools and how they’ve evolved to what they are today.

OBD1: The First Window into a Car’s Brain

Before the advent of sophisticated diagnostic tools and their intuitive interfaces, there was a humble beginning: the OBD1 system. Appearing in the late 1970s and early 1980s, OBD1 served as the first window into a car’s electronic brain.

How did OBD1 work? OBD1 was significantly simpler than its successor, OBD2. It primarily relied on a limited set of sensors monitoring specific engine functions, such as oxygen levels in engine exhaust. In case of a malfunction, the system would store a Diagnostic Trouble Code (DTC) in the Electronic Control Unit (ECU) memory. Mechanics would then use specialized diagnostic tools to read and decode these codes to identify the problem.

For more detailed information on the OBD1 system, please refer to our dedicated article on the Compu-Car blog: [Link to the article on Compu-Car blog]

Early Diagnostic Tools: Pioneers of ford Diagnostic tool

With the emergence of OBD1, specialized diagnostic tools began to appear. These early tools were often bulky and complex to use, requiring mechanics to have a good understanding of the vehicle’s electronic systems.

Innova 3145 Ford OBD1 Code Reader: An Example of Early Diagnostic Pioneers

The Innova 3145 was one of the pioneering diagnostic tools specifically designed for Ford, Mercury, and Lincoln vehicles equipped with the OBD1 system. Introduced in the 1980s, it became an essential tool in workshops dealing with these models.

Why was this device significant for Ford vehicles?

- Specialization: Designed specifically to read ford diagnostic codes , with the ability to store codes even after disconnecting the device from the vehicle, allowing mechanics to review codes later, ensuring high accuracy in diagnosing engine and overall vehicle issues.

- Self-Tests: The device allowed for self-tests on supported vehicle systems to ensure their proper functioning.

- Relative Ease of Use: It featured a relatively user-friendly interface for that era, making it easier for mechanics to read and understand fault codes.

- Wide Coverage: Supported most Ford vehicles manufactured between 1982 and 1995 equipped with the OBD1 system, including passenger cars and trucks, such as:

- Ford Mustang: 1982-1993 models

- Ford F-150: 1982-1995 models

- Lincoln Continental: 1982-1994 models

- Mercury Grand Marquis: 1982-1995 models

- Note: For precise supported models, refer to the device user manual or the manufacturer’s website.

-

Limitations:

- OBD1 Limitations: The device was constrained by the capabilities of the OBD1 system, meaning it could not read all types of data or perform all types of tests available in modern devices.

- Discontinued Support: With technological advancements and the emergence of OBD2, support for this device gradually ceased.

Challenges Faced by Mechanics with car diagnostic scanner

During this period, diagnosing vehicle faults was a challenging task requiring extensive experience and in-depth knowledge of vehicle systems. Mechanics faced numerous challenges, including:

- Limited Information: Information available on vehicle electronic systems was limited and primarily in print form, as computers and internet connectivity were not as readily available as they are today. This significantly increased the time required for fault diagnosis.

- Complexity of Devices: Early diagnostic tools were generally complex and difficult to use, requiring specialized training.

- Cost of Devices: Diagnostic tools were expensive and rare in the market, making them inaccessible to many repair shops.

- Locating the Diagnostic Connector: The diagnostic connector was not consistently located in the same place on all vehicles, requiring mechanics to search for it under the hood.

- Decoding Fault Codes: Some fault codes were ambiguous and required mechanics to have advanced knowledge of engine operation to decipher their meaning.

- Limited Database Coverage: Fault code databases were not always comprehensive, making it difficult to accurately pinpoint the cause of the problem.

OBD2: A Quantum Leap in Diagnostics

Following the foundation laid by OBD1, OBD2 revolutionized automotive diagnostics. OBD2 enabled the collection of vast amounts of data on engine performance and various systems, transmitting it to the Electronic Control Units (ECUs) with greater accuracy and speed. Furthermore, the standardization of Diagnostic Trouble Codes (DTCs) facilitated faster and more accurate fault diagnosis for mechanics.

Ford IDS: The Cornerstone of Ford Diagnostic scan tool

In parallel with the global advancements in diagnostic systems, Ford introduced its Integrated Diagnostic System (IDS). This system marked a significant leap forward in Ford vehicle diagnostics and programming.

The Evolution of VCM Devices

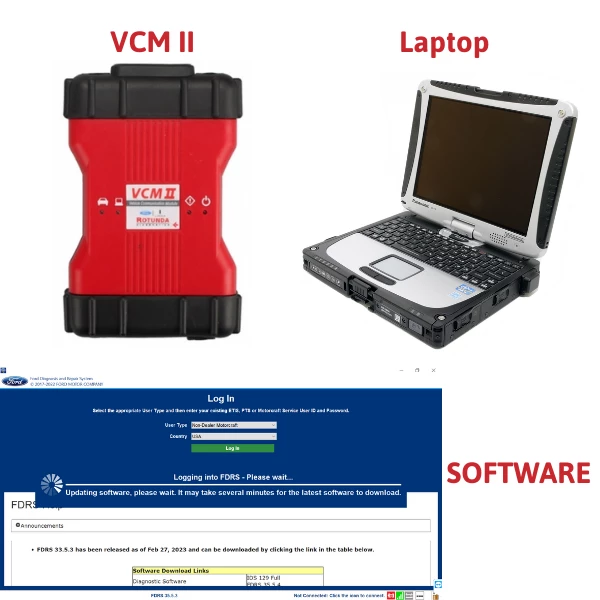

To enable the capabilities of the IDS, Ford relied on a series of communication devices known as Vehicle Communication Modules (VCMs). These devices, primarily designed and developed by Ford in collaboration with manufacturing partners, act as a bridge between the laptop and the vehicle’s system, allowing mechanics to access vehicle data, diagnose issues, and perform programming tasks.

-

VCM1: The Beginning:

The first VCM device was introduced in the 1990s, designed to support the first generation of Ford vehicles equipped with OBD2, dating back to 1996. VCM1 was primarily manufactured by Rotunda, a company specializing in providing diagnostic tools for the automotive industry. VCM1 continued to provide basic support for diagnostic, programming, and online programming operations for these models until 2015. However, with the advancement of technology, the increasing number of vehicle models, and the growing complexity of electronic systems, VCM1’s capabilities became limited.

-

VCM2: A Quantum Leap

In 2015, VCM2 emerged as the natural successor to VCM1. It offered enhanced support for modern protocols like CAN and covered all Ford models produced between 1996 and 2018. VCM2 excelled in comprehensive diagnostics, setting adjustments, programming electronic units, and featured online software updates, making it an indispensable tool for Ford mechanics.

-

Ford VCMM: An Integrated Solution

Ford VCMM (Vehicle Communication and Measurement Module) provided an integrated solution for diagnostics, combining the functionality of VCM II, the MTS 4000/4100 vibration analyzer, and advanced electrical measurement features. VCMM offered high performance and cost-effectiveness for users.

-

Ford VCM3: The Future

VCM3 represents the latest generation of diagnostic tools for Ford vehicles. It encompasses all the features of previous Ford VCM devices (VCM, VCM2, VCMM) and supports all Ford models produced since 1996, including electric and hybrid vehicles. VCM3 is primarily manufactured by Rotunda, but other versions from different companies are also available. VCM3 stands out with its support for CAN-FD networks, enabling it to diagnose the most complex electronic systems in modern vehicles. It offers a wide range of functions, including advanced diagnostics, resets, and online programming, making it the ideal solution for workshops working on all Ford models.

Software Used with VCM Devices

VCM devices interact with a range of specialized software to provide a wide array of functions, including:

-

Integrated Diagnostic System (IDS):

- Ford IDS is the primary ford diagnostic software used by technicians to access all diagnostic functions.

- It provides a user-friendly interface, enabling users to perform comprehensive diagnostics, read live data, and program electronic units.

- IDS works closely with VCM devices to ensure reliable communication between the computer and the vehicle.

- The annual license cost for Ford IDS is approximately 4000 Saudi Riyals. These licenses are sold by Ford directly through their online subscription portal.

-

J2534 Diagnostic Software (FJDS):

- This software is based on the J2534 standard, an industry standard for communication between diagnostic devices and the vehicle.

- FJDS offers a wide range of functions, including fault diagnosis, live data reading, and module programming.

- FJDS works well with modern VCM devices, especially VCM3, which fully supports the J2534 standard.

-

Ford Repair and Diagnostic System (FDRS):

- This software specializes in complex programming operations, such as updating the firmware of electronic units and performing calibrations.

- FDRS requires an internet connection to access the Ford database for the latest software updates.

- FDRS works closely with VCM devices, particularly VCM3, to provide a seamless and reliable programming experience.

The Relationship Between Software and VCM Devices

The mentioned software relies on VCM devices to communicate with the vehicle. The VCM device acts as an intermediary, transmitting data between the computer and the vehicle, allowing the software to diagnose faults and perform necessary adjustments. Each software program is designed to work with a specific version of the VCM device, so it’s crucial to use the correct software with the appropriate device.

Integration of Software and Hardware

The integration of software and VCM devices ensures accurate and efficient diagnostic and programming operations. By utilizing the latest software and VCM devices, mechanics can quickly and accurately diagnose faults and perform necessary repairs effectively. Furthermore, they can leverage the latest advancements in the automotive industry, such as electric and hybrid technologies.

In summary, the software and VCM devices work together to provide a comprehensive solution for diagnosing and programming Ford vehicles. Each component plays a vital role in ensuring the vehicle’s proper and efficient performance.

Important Notes:

- Variety of Manufacturers: This diversity indicates healthy competition in the VCM device market, contributing to improved product quality and increased options for users.

- Continuous Development: VCM devices and their accompanying software are constantly evolving to keep pace with advancements in automotive technology.

The Future of Diagnostic Tools: Competition Between Originality and Innovation

The automotive diagnostic landscape is witnessing continuous evolution, with modern technologies and artificial intelligence driving advancements in diagnostic accuracy and speed. Fierce competition between original equipment manufacturers (OEMs) like Ford and independent companies like Launch and Autel is pushing the boundaries of innovation.

Latest Technologies in Modern Car Diagnostic Tools:

- Intuitive Graphical User Interface: Modern diagnostic tools are designed with user-friendly interfaces, making it easier for technicians to understand data, diagnose problems, and navigate through various diagnostic functions quickly and efficiently.

- Comprehensive Databases: These tools contain extensive databases covering a wide range of vehicle models, enabling accurate and rapid fault diagnosis.

- Automatic Updates: Diagnostic tools and their accompanying software can be updated regularly via the internet, ensuring users have access to the latest technologies and fixes.

- Visual Diagnostics: Some tools utilize high-resolution cameras to inspect visual components of the vehicle, such as headlights and taillights.

- Integration with Mobile Devices: Some diagnostic tools can be connected to smartphones and tablets, providing greater flexibility for technicians.

The Role of Artificial Intelligence in Fault Diagnosis

Artificial intelligence is playing an increasingly important role in automotive diagnostics. AI-powered systems can analyze vast amounts of data to identify patterns and correlations that may be difficult for human technicians to detect. They can also predict potential failures before they occur, contributing to reduced maintenance costs.

Alternative Devices and Independent Companies in the Automotive Diagnostic Tool Industry

Original diagnostic tools face stiff competition from independent companies like Launch and Autel. These companies offer multi-purpose diagnostic tools capable of diagnosing and programming a wide range of vehicle models, including Ford vehicles. These alternative devices are known for their relatively lower cost, making them an attractive option for many workshops and independent mechanics. You can visit the Automotive Diagnostic Tools section on the Compu-Car website to explore the latest Launch and Autel devices: [Link to the Automotive Diagnostic Tools section on Compu-Car website]

Comparison Between Original and Independent Devices:

- Original Devices: Designed specifically for vehicles of the respective manufacturer, offering comprehensive coverage of all vehicle systems. They are known for their high diagnostic accuracy and a wide range of advanced functions, such as module programming and software updates. However, they are often more expensive and may require annual subscriptions for the latest updates.

- Independent Devices: Cover a wide range of vehicle models from various manufacturers and brands. They are known for their relatively lower cost and ease of use. These devices offer a wide range of basic functions, such as reading fault codes, displaying live data, and often performing most programming operations within the vehicle. In some models, they may even connect to online accounts and perform online programming operations. However, they may not provide the same level of accuracy and advanced features as original devices.

The Future of Diagnostic Tools: Competition Between Originality and Innovation

The competition between original and independent Car diagnostic tool manufacturers is driving innovation and pushing the boundaries of diagnostic capabilities. This competition will continue to lead to the development of more advanced and efficient Car diagnostic Scanner.

Conclusion

The field of automotive diagnostics is constantly evolving, with modern technologies and artificial intelligence contributing to increased diagnostic accuracy and speed. The fierce competition between original equipment manufacturers and independent companies provides users with a diverse range of options, enabling them to choose the most suitable tool for their specific needs.